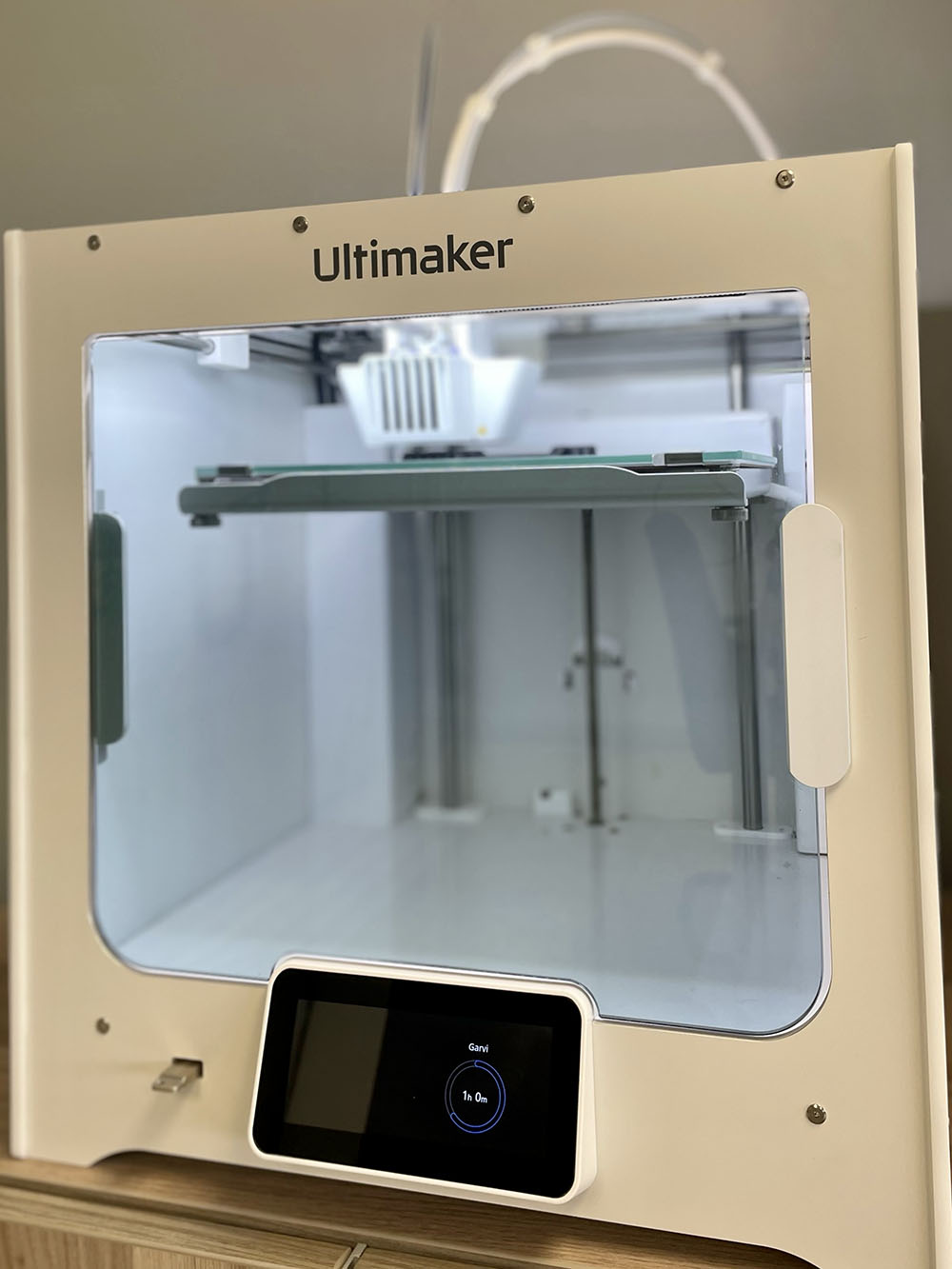

In recent years, 3D printing has emerged as a revolutionary technology that promises to transform the way we design, manufacture and create products. With its ability to build three-dimensional objects from digital models, 3D printing has captured the imagination of professionals, enthusiasts and businesses around the world. Below we will take an in-depth look at what 3D printing is, what it is used for and what its most prominent benefits are.

3D printing, also called additive manufacturing, is a process that creates three-dimensional objects from digital models. Using a 3D printer we can create the desired object. In our case, prototypes of metal parts for subsequent assembly line production.

Uses:

· Rapid prototyping: Allows us to create prototypes of products quickly and economically.

· Customisation: Allows the manufacture of unique objects adapted to individual needs.

· Aerospace and automotive: Used to manufacture lightweight and complex parts, improving efficiency and performance.

Benefits:

· Customisation: Allows products to be manufactured tailored to individual needs and preferences.

· Reduced costs and production times: Eliminates the need for expensive tooling and speeds up product development.

· Complex design and geometry: Enables the creation of objects with complicated and optimised shapes.

· Sustainability: Produces less waste and allows parts to be repaired, reducing waste.

3D printing has revolutionised manufacturing by offering new possibilities in several fields. Its ability to customise, reduce costs, create complex designs and be sustainable make it a promising and successful technology for the future of Garvi Industrial and our customers.