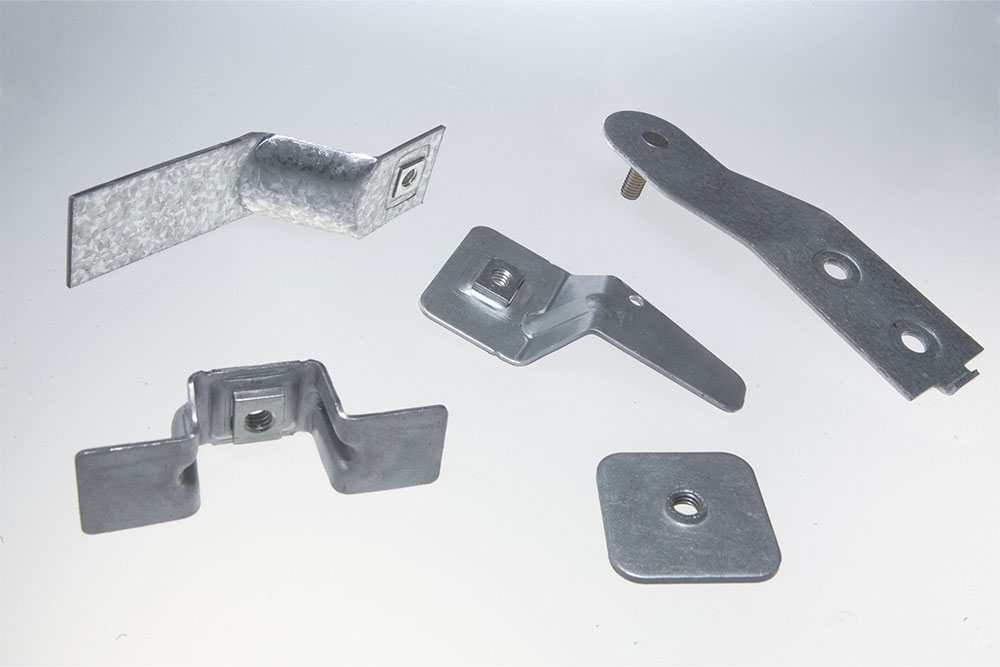

The automotive industry is constantly evolving and developing new technologies to improve the efficiency, safety and quality of vehicles, and one of the key processes in automotive manufacturing is metal stamping, a technique that has revolutionised the production of components and bodywork.

There are many advantages of metal stamping in the automotive sector:

1. Efficient production: it allows complex parts to be manufactured quickly and efficiently. Automated processes and high production speeds reduce manufacturing times and associated costs.

1. Efficient production: it allows complex parts to be manufactured quickly and efficiently. Automated processes and high production speeds reduce manufacturing times and associated costs.

2. Lightness and strength: Allows the production of lightweight but highly resistant components. This is especially important in the automotive industry, as weight reduction contributes to improved fuel efficiency and reduced emissions of polluting gases.

3. Design flexibility: Allows the creation of complex shapes and the integration of functional features, such as impact absorption elements and airflow channels. This gives automotived esigners the freedom to create more aerodynamic and visually appealing vehicles.

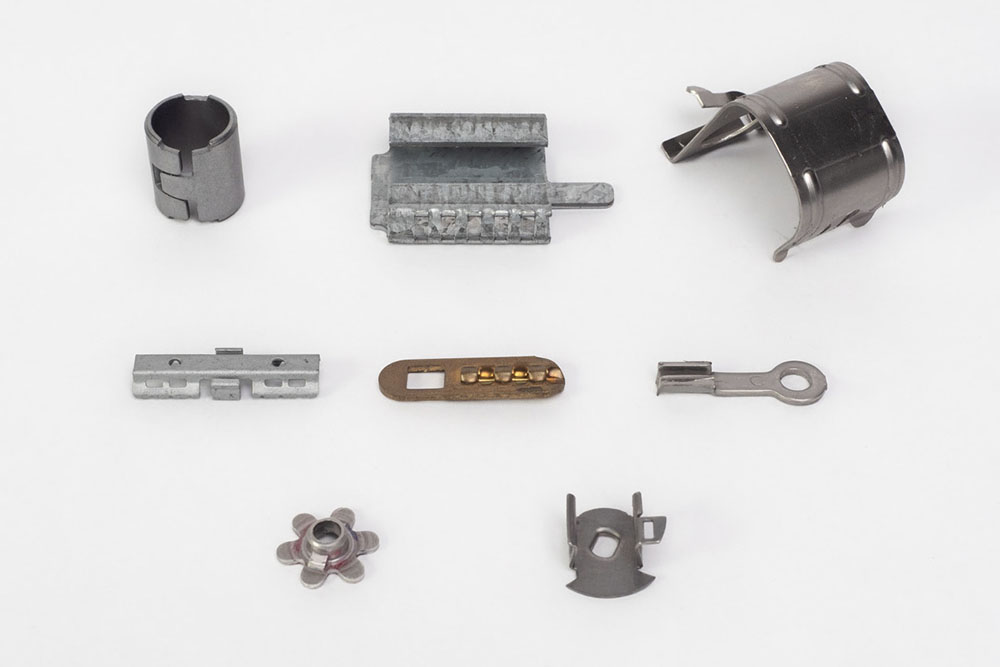

4- Innovation: Prototyping can be done by machining (CNC) and 3D printing, also known as additive manufacturing.

Machining is a manufacturing process that removes material from a blank to shape a final component.

Advantages:

· Dimensional accuracy: Machinings are known for achieving very tight tolerances and high dimensional accuracy.

· Dimensional accuracy: Machinings are known for achieving very tight tolerances and high dimensional accuracy.

· Material variety: They can work with a wide range of materials, including metals, plastics and composites.

3D printing, or additive manufacturing, builds objects layer by layer from digital data. It allows a customised service to be given to customer needs by creating prototypes of metal parts for subsequent assembly line production.

Advantages:

· Rapid prototyping: Allows components to be created quickly and economically.

· Personalisation: Unique objects adapted to individual needs.

· Reduced costs and production times: Eliminates the need for expensive tooling and speeds up product development.

· Complex design and geometry: Enables the creation of objects with complicated and optimised shapes.