Key materials in metal stamping

At Garvi Industrial, we understand that the choice of material is one of the pillars to achieve high quality metal components. Each sector, application and part has its own requirements, and we have the experience and technical capacity to offer a tailor-made solution. What materials do we work with? Over the years we have developed […]

Garvi Industrial: Over four decades of innovation and leadership in metal stamping

Since our humble beginnings as Arvi in 1969, we have evolved to become a leading company in the metal stamping sector, especially in the automotive industry. Our history, which began in the iconic Batlló factory in the Sants neighbourhood, is marked by a constant commitment to quality, innovation and the continuous improvement of our production […]

From coil to component: Integral solutions in metal stamping

Garvi Industrial, we specialise in the progressive and transfer stamping of metal components. We transform raw metal material into high precision parts and assemblies, mainly for the automotive sector. We control every stage of the manufacturing process, ensuring quality, efficiency and total traceability for our customers. We work with a wide range of metal materials, […]

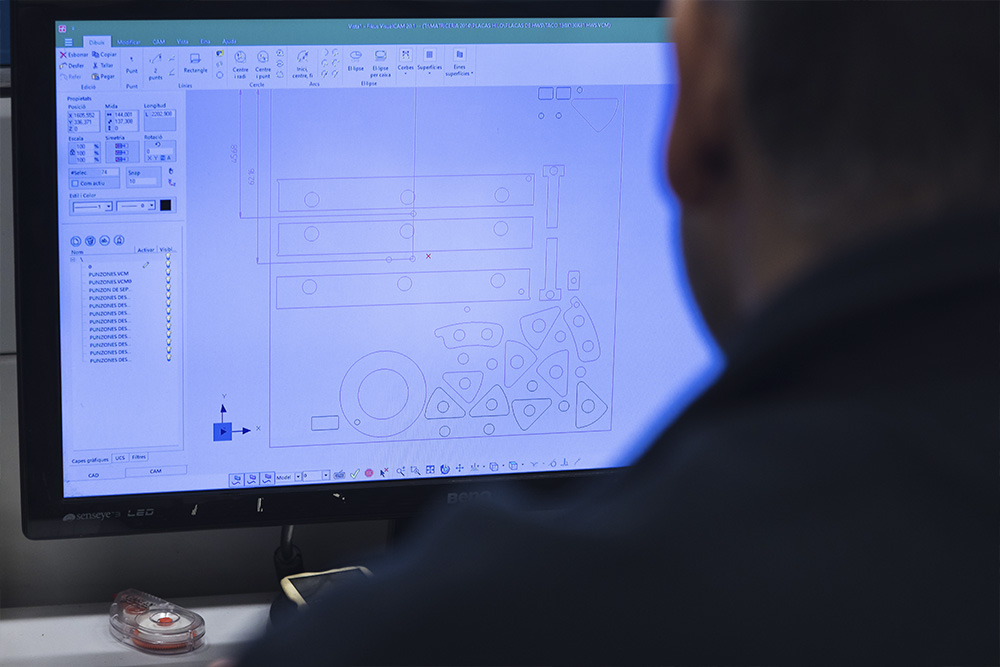

Innovation and Precision: Discover our new tooling section

As part of our process of renovation, continuous improvement and optimisation, we have moved our tooling section to a new building. This has allowed us to: – Create a more efficient layout. – To enlarge the machinery. – Provide our staff with a more comfortable working environment. With this we aim to: – Optimise our […]

Garvi Industrial S.A.’s commitment to sustainability in metal stamping

Sustainability has gone from being a trend to become an essential pillar for modern industry. At Garvi Industrial S.A., we are fully committed to adopting responsible practices in our metal stamping processes. This approach not only allows us to meet the growing demands of our customers, but also to actively contribute to the care of […]

FUNDAMENTAL PILLARS THAT GUARANTEE OUR EXCELLENCE

Our commitment to quality is backed up by extensive experience and knowledge in the sector to give our customers the confidence they need to choose us as their metal stamping supplier. For this reason, our four fundamental pillars are essential to guarantee excellence in all our work: QUALITY: Our focus is on guaranteeing that the […]

CONTINUOUS IMPROVEMENT

At Garvi Industrial we have taken important steps to strengthen our relationship with our customers. Our main focus is to listen carefully to them and adapt our products and services to their specific needs. Garvi has also invested heavily in improving its manufacturing capabilities by adopting new technologies. This allows us to offer more customised […]

Strengthening the R&D department

At Garvi Industrial we have taken an important step to strengthen our R&D department.In recent months, several highly qualified engineers and technicians have joined our team, who will contribute their experience and knowledge to further boost innovation and the development of new products. These new talents join our existing team, forming a strong multi-disciplinary group […]

Cold stamping

At Garvi Industrial, we pride ourselves on our outstanding ability to manufacture high quality metal parts. We are experts in the cold stamping of metal parts. What is cold stamping? It is a process in which we start with sheet metal in coil (1) and shape it by applying forces (2) until the desired shape […]

Innovation in the automotive sector thanks to metal stamping

The automotive industry is constantly evolving and developing new technologies to improve the efficiency, safety and quality of vehicles, and one of the key processes in automotive manufacturing is metal stamping, a technique that has revolutionised the production of components and bodywork. There are many advantages of metal stamping in the automotive sector: 1. Efficient […]